Tungsten Carbide Nozzle Fitting

We are a professional tungsten carbide nozzle fitting manufacturer which can produce many different kinds of nozzles, such as spray nozzles, oil nozzles, blasting nozzles and so on.

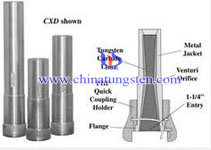

Tungsten carbide nozzle fitting is made by the precision machining with the tungsten carbide materials (super hard alloy). The hardness reached over HRA90 degree while the anti-bending degree reached over 2300N/mm. On machining tungsten carbide nozzle fitting, we do the precision grinding and surface treatment to achieve Ra0.1 of the bore roughness and the Ra0.025 of the R place of both ends. There is a scientific curvature radius design in the both entrance. This design can ensure a smooth transit of the thread. Due to the overall materials processing, and no elevation in the bore, the phenomenon of easy-bending and plugging has been improved comparing with the ruby nozzle.

Tungsten Carbide Nozzle Fitting Application

With high speed to wash, well wear resistance, excellent corrosion resistance, tungsten carbide nozzle fitting often be used in agricultural irrigation and urban greening. Used in geological prospecting, machinery tool manufacturing and serves as drill bit in wind drill and electric drills for coal digging Fit for precision lathe are used in nonstop cutting of die-cast iron.

Tungsten carbide nozzle fitting offers long life and economy when rough handling cannot be avoided, and where medium cutting abrasives (glass bead, steel shot & grit, mineral or coal slag) are used. Traditionally, tungsten carbide is the material of choice for general nozzle applications. Tungsten carbide nozzle fitting is widely used in such industries as surface treating, sandblasting and painting, electronics, chemical processes. Tungsten carbide nozzle fitting is also used in different applications like for wire straightening, wire guides and others.

Tungsten Carbide Nozzle Fitting Advantages

Common nozzle materials include cast iron, ceramic, tungsten carbide, silicone carbide, and boron carbide. Cast iron nozzles are now very rare as they wear out after just 6 to 8 hours. Ceramic nozzles are used only with non aggressive abrasive in light duty equipment and blast cabinets. Tungsten, Silicon, and Boron Carbide are the most popular for the majority of blasting applications due to their long life. Comparisons among tungsten carbide nozzle fitting and other nozzles service life are listed below.

If you have any interest in tungsten carbide products, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone: +86 592 5129696.

sales@chinatungsten.com

sales@chinatungsten.com