Cemented Carbide Tools Drilling Principle

Cemented carbide tool drilling principle includes drilling dosage , cutting layer parameters and cutting layer during the drilling characteristics and drilling dosage of selection.

Cemented carbide tool drilling principle - drilling dosage and cutting layer parameters

| Cemented Carbide Tool Drilling Principle -Drilling Dosage | Cemented Carbide Tool Drilling Principle -Cutting Layer Parameters |

|

|

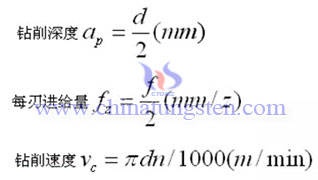

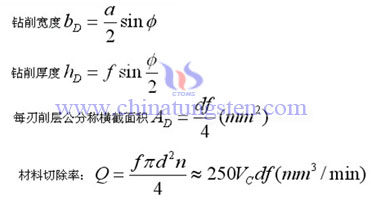

| Drilling dosage includes three elements: cutting depth (drilling depth) αp amount of feed ?, cutting speed Vc. | Cutting layer parameters include drilling thickness the hD, drilling width bD, each blade cutting layer nominal cross-sectional area of AD, material removal rate Q. |

Drilling process characteristics

1. Drilling deformation characteristics and chip shape

Deformation law of the drilling process and turning. But the cemented carbide tool drilling is carried out in the semi-enclosed space, the transverse edge of the cutting angle and is not reasonable, makes it more complicated drilling deformation. Mainly in the following points:

1) Drilled concrete cores at drilling before the cutting edge angle is negative, in particular, is a cross-blade area, cutting scraping extrusion swarf grainy and was crushed. Almost zero diameter of cemented carbide tool drilling discrepancies in the actual area, the cutting speed is close to zero, but still feed motion, so that discrepancies in the actual the chisel area work after angle is negative, equivalent to the use wedge angle is βoψ the chisel hack into the workpiece, called the wedge hack squeezed. This is the main reason to cause the cemented carbide tool drilling axial force increases.

2) Before cemented carbide tool drilling the main points of the cutting edge angle, edge inclination, so that the chip deformation, curling flows, and chip removal is influenced by the spiral grooves. Cutting the plastic material, the chip volume is a conical spiral. Chip breaker comparison difficult.

3) Cemented carbide tool drilling edges, with no posterior horn and the hole wall friction. The easy processing plastic material produced cattle BUE stick blade tape affect the quality of cemented carbide tool drilling.

2. Drilling force

Drilling the drill of each cutting edge are generated cutting force, including the tangential force (main cutting), backward force (radial force) and the feed force (axial force). When the symmetry of the left and right cutting edge, back force offset ultimately constitutes the drill feed force Ff and the cutting torque Mc.

3. Drill wear characteristics

The main reason for high-speed steel drill bit wear phase transition wear. Wear the process of law and turning tools. Uneven load of the various points of the drill blade, the outer circumferential cutting speed is highest, so it wears most serious. Drill holes or deep hole drill bit wear often cemented carbide tool drilling force does not exceed a certain limit as the standard. When the torque or feed force exceeds the alarm device signals to control the automatic retraction.

There are many factors affect the durability of drill, including: drill material and heat treatment conditions, drill structure, edge parameters, cutting conditions. The higher the hardness of the drill bit, the structural rigidity of the better, blade-shaped geometric parameters and processing of material with the more reasonable, the higher the degree of sharpening symmetrical cutting with halo optimization of the more reasonable, the higher the bit life.

Cemented carbide tool drilling principle - drilling dosage selection

Drill diameter: determined by the process size, drilled holes required at once as possible. When machine performance is incapable, then use cemented carbide tool drilling then reaming process first. Need reaming, cemented carbide tool drilling diameter taken a pore size of 50% to 700%. Reasonable sharpening and grinding can effectively reduce the feed force to expand the scope of the machine tool drilling diameter.

2. Feed: Usually the drill bit by the drill feed amount of rigidity and strength limitations. The large diameter drill only by the limit of the rigidity of the machine tool path of institutional power and process systems. Ordinary drill feed rate empirical formula to estimate: ? = (0.01 ~ 0.02) d, reasonably grinding drill bit selection ? = 0.03d. The drill diameter is less than 3 ~ 5mm, commonly used in manual feed.

3. Drilling speed: cutting speed of high-speed steel drills can also refer to the relevant manual data selection.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase [email protected], [email protected] .