Boring & Cemented Carbide Boring Tools

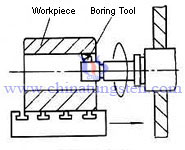

Boring is a turning process to expand the inner diameter of the hole or other circular contour with boring tools, the boring processing applications generally range from semi-roughing to finishing, with the boring tool is usually single-edged boring cutter.

Boring generally carry out on boring machine, processing center and a combination of machine tools, boring mainly used in the processing box, bracket and stand on the workpiece cylindrical bore, threaded holes, holes, grooves and face; When using a special attachment.When boring can be processed inside and outside the spherical cone.

| Boring |

|

Boring characteristics:

①Boring surface trajectory is boring tools on the machine spindle rotary movement. Boring and drilling is similar;

② While boring ,as the boring tool is mounted on the shank extends into the inner bore cutting Therefore, the boring processing is performed in a semi-closed state where the work.

③ Boring workpiece clamping on the bench, longitudinal, vertical movement by the boring bar or table for longitudinal and lateral movement of the feed motion of the workpiece.

④While boring, because of the boring tool flank and the workpiece bore surface friction and boring bar cantilever extension, the boring knife cutting poor conditions, and cause vibration.

⑤ Boring applications fine-tune the boring tool, boring tool and special fixtures or boring mold sizing can accurately guarantee the aperture (H7 ~ H6), Pitch (0.015mm) accuracy and low surface roughness values (Ra = 1.6 ~ 0. 8μm), Therefore, the boring processing is an important process for the precision working holes boring holes of processing suitable for the large box and non-rotating parts (particularly large holes and long holes) processing.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase [email protected], [email protected] .