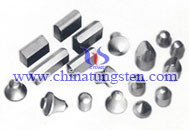

Cemented Carbide Mine Tools

Mining machines use cemented carbide mine tools. The button bits slot into the head of the boring machine. The individual carbide tips grate against the rock face and shuck off rock chips. Carbide alloys last longer then steel alloys, are more corrosion resistant and withstand greater amounts of heat. Some mining operations involve spraying water to keep down dust and cool off the drill tips. Steel tips rust fast in this environment, so carbide tips are used when possible.

| Cemented Carbide Mine Tools | |

|

Cemented carbide mine tools are widely applied for rock tools, mining tools for use in quarrying, mining, tunnelling and construction. |

Cemented carbide mining tools, such as conical bits, roof bits, flats radials, etc. have evolved over the years. Currently, these tools consist of cobalt-bonded, tungsten carbide bits brazed to steel shanks. When properly processed, long-lasting tools are produced which combine great strength, toughness and high hardness.

Cemented carbides, or hard metals as they are also called, are produced by cementing ultra-hard tungsten carbide (WC) grains in a binder matrix of cobalt metal by liquid-phase sintering. The high solubility of WC in cobalt at elevated temperature and the excellent wetting of WC by the liquid cobalt results in superior densification during liquid-phase sintering, and a pore-free structure. As a result, material is produced which combines great strength, toughness, high hardness and wear resistance, and is also readily brazed, which is not the case for pure tungsten carbide. The high hardness is necessary for the tools to function effectively in their working environment. While the various varieties of coal are generally soft, many of the associated minerals are abrasive, causing excessive wear to metal tools.

Cemented carbide mine tools are produced by a joining process called brazing, which is a well-established commercial process capable of producing strong joints. It is widely used in industry because of its ability to join most metallic materials, including dissimilar metals.

Cemented carbide mine tools are made to be used on modern machining centers. These drill bits are manufactured with fine-grain carbide and titanium aluminum nitride (TiAlN) coatings to provide long tool life. As self-centering drills, they have a specially designed edge that helps to control chips and chip evacuation in most workpiece materials. The self-centering geometry and fine tolerances of solid-carbide drills ensure quality holes without additional machining. Cemented carbide drills that have exchangeable cemented carbide tips incorporate a steel body with the exchangeable tips that are known as crowns.

These tools offer the precision of brazed drills, and offer increased productivity at reduced operating costs. The carbide crowns used with this new generation of drilling tools are available in precise size increments and have a self-centering geometry to produce close diameter tolerances.

Cemented carbide mining tools are used in coal cutter drilling tools, Mine machinery tools. Cemented carbide Mining Button Bits are widely applied for Rock tools, mining tools for use in quarrying, Mining, Tunnelling and Construction.

Chinatungsten Online produces any standard sizes and other styles are available on customers' requests with higher quality guaranteed by HIP sinter.